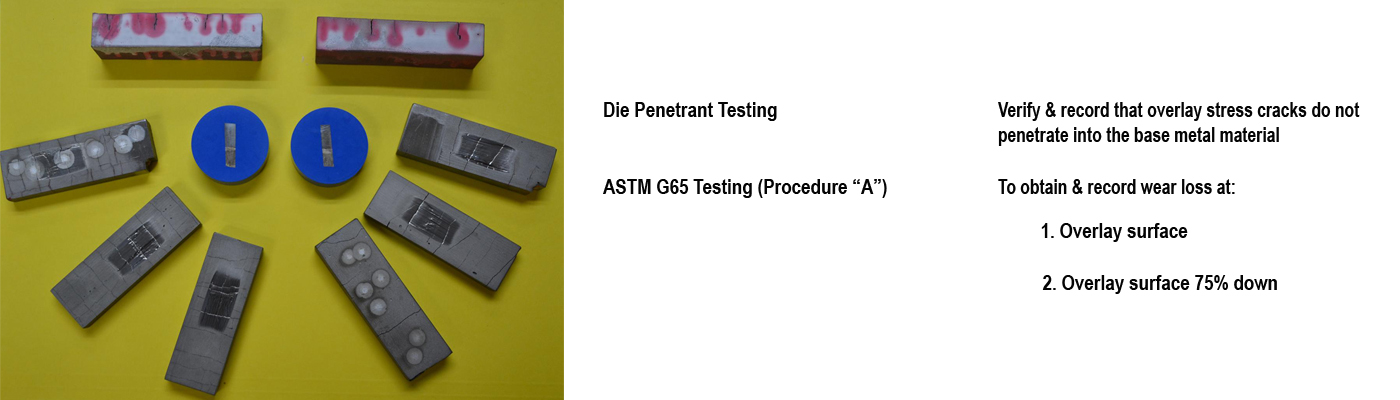

Nibrock, Inc. constantly monitors its production of Rock Plate and Rock Pipe. Production test are taken from each overlay table and pipe machine during the first week of each month. Nibrock, Inc’s production testing will consist of; Surface & Through Hardness, Photo Microstructure, Die Penetrant and As Welded Chemical Analysis. The above listed testing, along with ASTM G65 Procedure “A” Abrasion Testing is available upon Customer request.

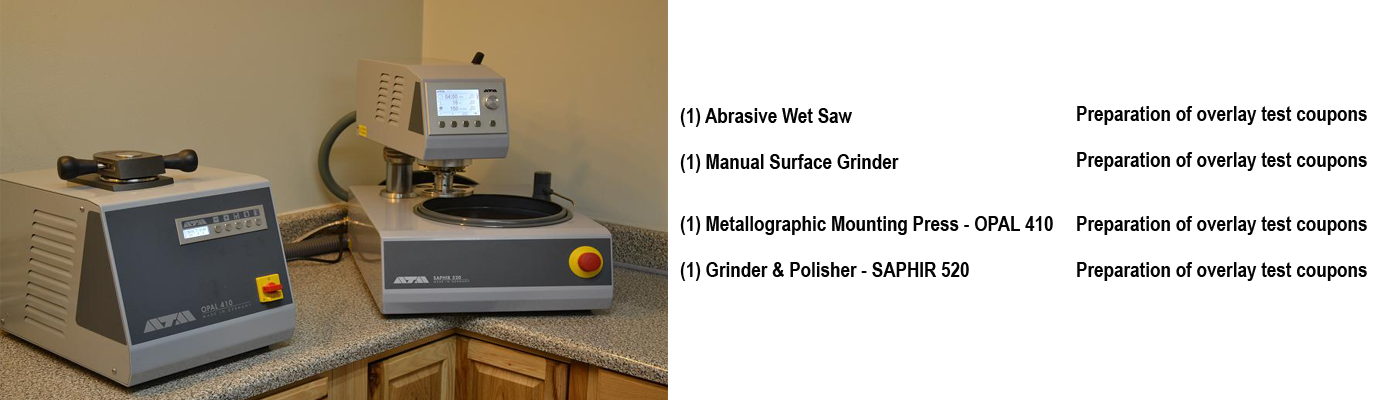

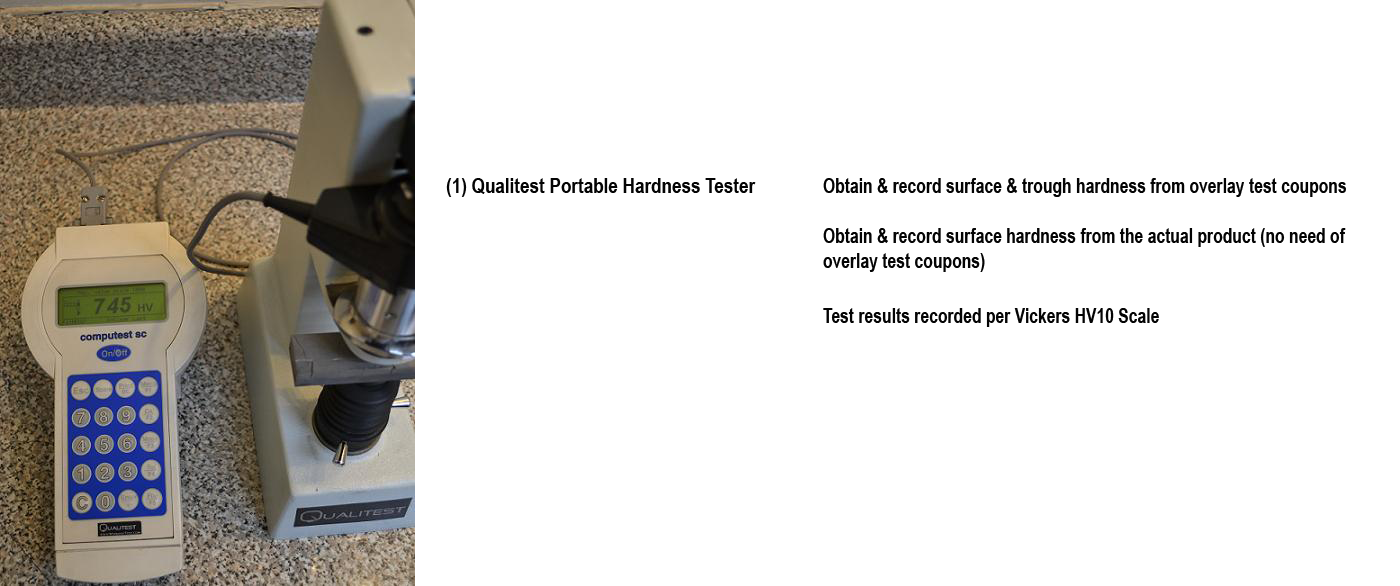

Nibrock, Inc’s Testing Equipment and Purpose:

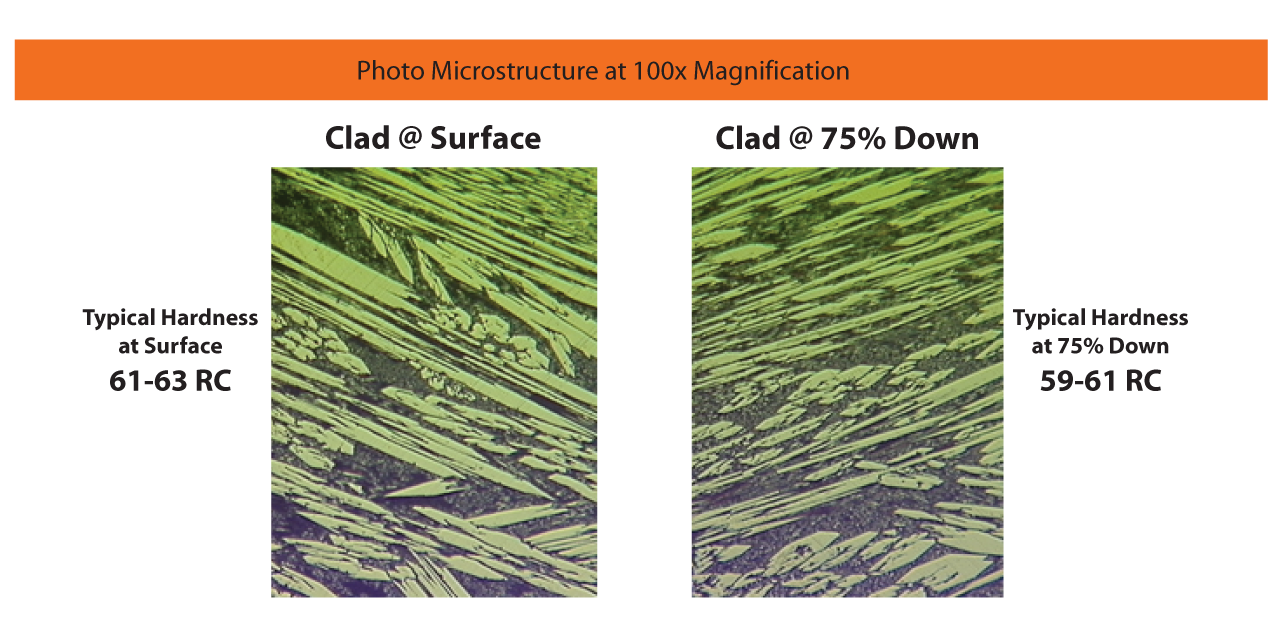

Typical Test Results for CCO Double Pass Rock Plate and Rock Pipe:

| Location | Description | Vickers | Rockwell HRC | Location |

| 1 | Test Sample 550-01 | 782 | 63.3 | Surface |

| 2 | Test Sample 550-01 | 769 | 62.8 | Surface |

| 3 | Test Sample 550-01 | 771 | 62.9 | Surface |

| 4 | Test Sample 550-01 | 778 | 63.2 | Surface |

| 5 | Test Sample 550-01 | 764 | 62.6 | Surface |

| Location | Description | Vickers | Rockwell HRC | Location |

| 1 | Test Sample 550-01 | 779 | 63.2 | CCO Weld |

| 2 | Test Sample 550-01 | 772 | 62.9 | CCO Weld |

| 3 | Test Sample 550-01 | 781 | 63.3 | CCO Weld |

| 4 | Test Sample 550-01 | 774 | 63 | CCO Weld |

| 5 | Test Sample 550-01 | 758 | 62.4 | CCO Weld |

| 6 | Test Sample 550-01 | 755 | 62.2 | CCO Weld |

| 7 | Test Sample 550-01 | 242 | – | Base Metal |

| 8 | Test Sample 550-01 | 248 | – | Base Metal |

Report# 2181

Machine: Falex ATM S/N AT-88-019

RPM: 200

Force: 30lb

Distance: 6000 Revolutions

Media: AFS 50-70

| Description | Initial Weight (g) |

Final Weight (g) |

Mass Loss (g) |

Assumed Density (g/cm3) |

Volume Loss (mm3) |

Wheel Diameter | |||

| Start | Finish | Loss (in) | AVL (mm3) | ||||||

| 1100-05-8 (Surface) | 215.1015 | 214.9653 | 0.1362 | 7.68 | 17.73 | 8.834 | 8.833 | 0.001 | 18.07 |

| 1100-06-8 (75%) | 193.7313 | 193.5942 | 0.1371 | 7.68 | 17.85 | 8.812 | 8.811 | 0.001 | 18.23 |