Rock Pipe, manufactured in the USA, is a composite wear pipe consisting of a high chromium carbide weld overlay applied to a low carbon steel (most common) base pipe. The chromium carbide weld overlay is used for its corrosion, severe abrasion and moderate impact features. Rock Pipes chromium carbide weld wire is manufactured to Nibrock, Inc.’s proprietary specifications and is applied with the FCAW (Automatic / Semi-Automatic) Welding Process. With the selection of the low carbon steel base pipe that provides for the ductility and weld ability that is ideal for shop fabrication and field installation, the unique characteristic of Rock Pipe is completed.

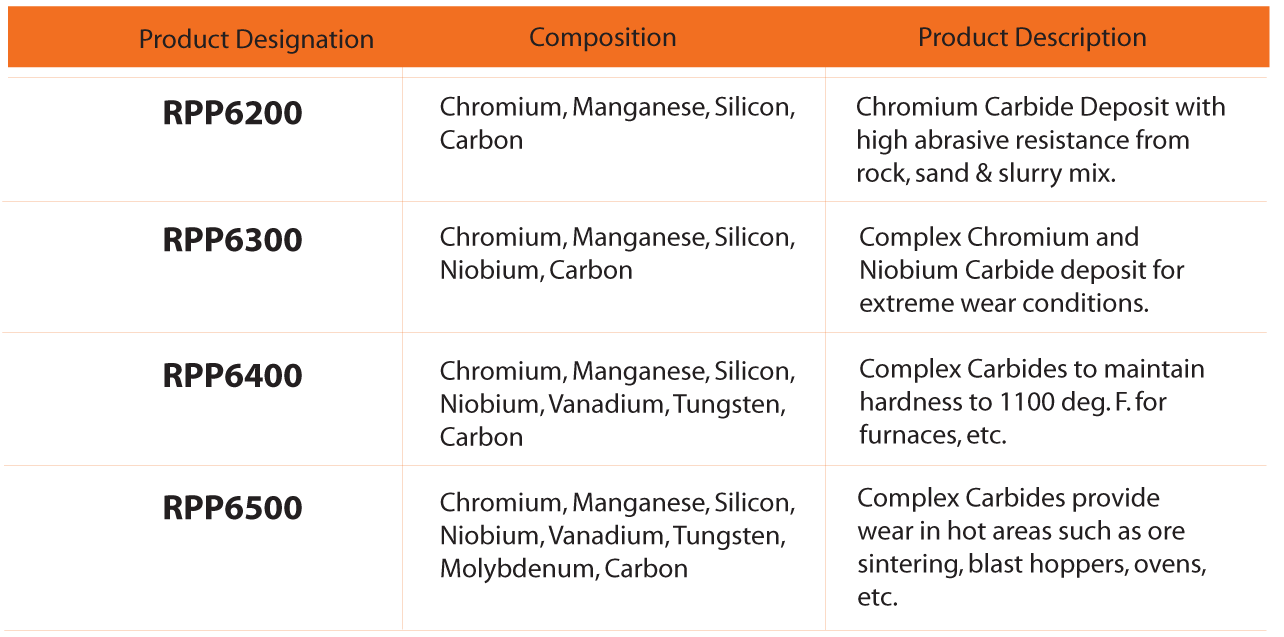

Nibrock, Inc.’s common types of Rock Pipe produced:

* Custom alloys of pipe base metal and weld overlay are available upon request.

Nibrock, Inc. currently has the following equipment for producing chromium carbide Rock Pipe. Rock Pipe can be produced with standard circumferential stringer weld beads or longitudinal oscillated weave welds. Both options will have an overlay weld penetration into base metal of 1/32” Min. / 3/32” Max. and can be applied to both the inside and outside diameters of Rock Pipe.

- (1) 1-Head Pipe Machine with the capability to produce Rock Pipe 2” Diameter x 3’ Long

- (1) 1-Head Pipe Machine with the capability to produce Rock Pipe 3” to 12” Diameter x 5’ Long

- (1) 3-Head Pipe Machine with the capability to produce Rock Pipe 8” to 24” Diameter x 20’ Long

- (1) 3-Head Pipe Machine with the capability to produce Rock Pipe 14” to 48” Diameter x 20’ Long

- (1) 3-Head Pipe Machine with the capability to produce Rock Pipe 16” to 60” Diameter x 20’ Long

Standard Rock Pipe chromium carbide overlay thicknesses consist of:

- 1/8”, 3/16” and 1/4” (Single Pass)

- 1/4”, 5/16”, 3/8” and 1/2” (Double Pass)

* Custom weld overlay & base metal thicknesses as well as custom diameters are available upon request

* Chromium carbide overlay thickness cannot exceed base metal thickness

* Standard Pipe Fittings with custom alloys of base metal and weld overlay available upon request

Typical Chromium Carbide Wire Chemistry (Undiluted)

- Carbon: 6.50 %

- Manganese: 2.50 %

- Silicon: 1.25 %

- Chromium: 30.00 %

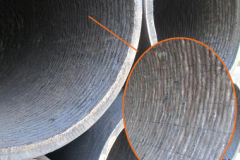

Appearance

- The chromium carbide overlay surface of Rock Pipe will consist of standard circumferential stringer weld beads or longitudinal oscillated weave welds. Numerous hairline type stress relief cracks will appear on the chromium carbide overlay surface during the welding process. These stress relief cracks, being a natural characteristic of chromium carbide overlay, do not penetrate into the base metal material.

Straightness

- Rock Pipe has a straightness tolerance of 3/32” per 39.375″